Products

SoC-MERITEK’s Core Technology

The MBs-PLC’s design incorporates a “System on Chip” (SoC) developed in-house by Meritek Corporation. The BGA chip consists of over 120,000 gates which integrates powerful features such as a Central Processing Unit (CPU), Memory, Hardware Logic Solver (HLS), 5 high-speed communication ports, 4 sets of hardware high-speed counters/timers, 4 axes of high-speed pulse outputs for NC positioning control (with linear interpolation), 16 high-speed interrupts and captured inputs. The MBsPLC represents high functionality and reliability with exceptional value compared to other PLC’s in its class.

User friendly and powerful instructions

The MBs-PLC has more than 300 instructions which adopts a user friendly and readable multi-input/multi-output function structure. With this multi-input instruction structure the user can derive many types of functionality which other brands of PLC’s may require the use of many instructions to achieve this. Also the operation result can be directly sent to internal or external outputs. To increase the program readability, the inputs or outputs for each function instruction have their own mnemonic symbol attached and the content of each operand is also displayed. For high-end applications, such as PLC networking (LINK), PID control and NC positioning etc, the MBs-PLC provides dedicated convenient instructions to assist in program development.

Communication function

Via the five high-speed communication ports included in the SoC, the MBsPLC’s communication capability is outstanding operating at a maximum speed of 921.6Kbps. Communications can be achieved using ASCII code or the double-speed binary code. Along with MERITEK’s standard protocol, Modbus ASCII/RTU/TCP or user-definable protocols are also available. The MBs-PLC also provides the option of 8 different communication boards and 10 different communication modules for various types of communication applications. With their high speed and functionality the MBs-PLC has the greatest number of communication ports than any other PLC in its class. Each communication port comes standard with LED indicators for transmission (TX) and reception (RX) to enable the user to monitor the operation.

PLC & NC Control in one and Dedicated NC Positioning Language

NC Position Control is incorporated into the SoC of the MBs-PLC which integrates PLC+NC control into one unit in order for resources sharing and reducing the need of data exchange. The NC position control adopts special positioning command language, which allows programming by mechanical or electrical units and the changing control of parameters during execution. One single unit has up to four axes outputs with a maximum frequency of 200KHz (MC) or 920KHz (MN) and equipped with multi-axis linear interpolation function. If combined with the four sets of built-in HHSC, it can achieve a fully closed loop positioning control!

Integrated high-speed counters with counting frequency up to 920 KHz

The MBs-PLC includes up to 4 sets of hardware high-speed counters (HHSC) and 4 sets of software high-speed counters (SHSC). The highest counting frequency of a HHSC is 200KHz (MC) or 920KHz (MN). Each HHSC also has a clear and mask function. There are 8 counting modes including U/D, U/ Dx2, P/R, P/Rx2, A/B, A/Bx2, A/Bx3 and A/Bx4 which makes the HHSC very powerful and efficient. For example, if the encoder, running at 200 pulses per revolution, adopts A/Bx4 mode the MBs-PLC can achieve the same result that 800 pulses per revolution encoder can provide. The counter is implemented in the hardware so as not to occupy CPU processing time. In addition, 4 sets of software high-speed counters (SHSC) has U/D, P/R, A/B 3 types of counting modes and the total counting frequency is 5KHz.

High-speed timers

The MBs-PLC is the only PLC in this class providing 0.1mS high-speed timers (the MBs-PLC having one 16-bit and 4 sets of 32-bit HST). Currently, the fastest time base of high speed timers used in other brands of PLC’s is 1mS. By incorporating the interrupt function of the MBs-PLC the accuracy of 0.1mS time base high-speed timer of MBs-PLC is further enhanced and can easily achieve more precise speed detection or can be used as a frequency meter. In most cases, expensive speed detection equipment can be replaced by the economical MBs-PLC.

MERITEK’s Powerful Communication Features

The five communication ports in MBs-PLC can simultaneously connect to various intelligent peripherals with various interfaces such as USB, RS232, RS485, Ethernet, CANopen® and ZigBee™. Apart from the MERITEK and Modbus protocol or communication through the MERITEK communication server, the user can also use the PLC’s CLINK instruction for user-defined protocol to actively or passively establish connections with many intelligent peripherals.

Open communication driver

The open communication protocol of the MBs-PLC is supported by all major brands of Supervisory Software (Scada) and Operator Terminals (HMI). Scada software such as Wonderware, Citec, Labview and LabLink! Operator terminals (HMI) such as Proface, Hitech/Beijer and Cermate can be directly connected with the MBs-PLC via serial and Ethernet interfaces. MERITEK also provides MERITEK DDE standard communication server or thirdparty OPC server for the user to easily connect the MBs-PLC to various control or supervisory systems. In addition, reputable companies such as National Instruments and KONTRON both sell MERITEK OPC software package for users.

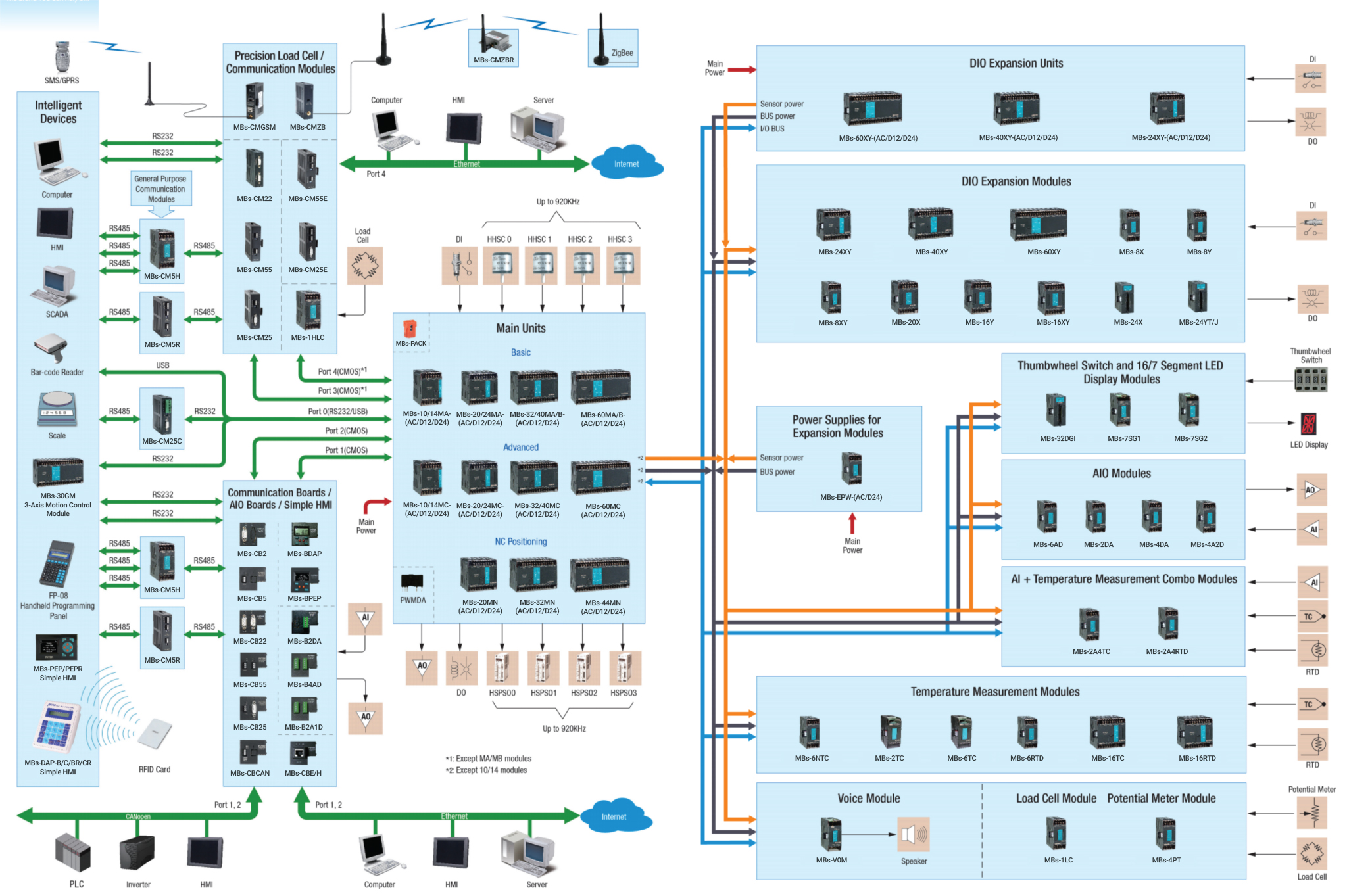

Complete range of peripherals

In addition to over 200 models of main CPU units, the MBs-PLC also provides about 100 models of expansion I/O for selection. The expansion I/O modules include basic DI/O, AI/O and other communication modules, also include thumbwheel switch input module, 16/7 segment LED display module, 8 types (J, K, R, S, E, T, B, N) thermocouple, Pt100, Pt1000 RTD temperature measurement modules. There is also a new additions to the range including load cell module used in weighting, potential meter module used in measuring position, and a user-friendly voice module. The MBsPLC also provides a MBs-DAP or MBs- PEP simple HMI which can be linked together with a single RS485 bus. The MBs-DAP or MBs-PEP can be a simple Timer/Counter editor or it can also be used as a simple human machine interface through the function of user definable keys and message display. The MBs-DAP or MBs-PEP can be equipped with a wireless RFID sensing module and can be applied to such applications as entrance control, parking equipment and elevator control amongst others.

User-friendly operating environment

“WinProladder” is the Windows-based ladder diagram programming software for the MBs-PLC. It provides a user-friendly operating environment with editing, monitoring and debugging functions which allows the user to become familiar with the operation of the software in a very short time. The powerful editing function of WinProladder, assisted with keyboard, mouse and on-line help (of ladder instructions and operating guide) greatly reduces programming development time. Features which can display the data registers directly in the ladder diagram and provide multiple status pages for monitoring gives the user the ability to monitor and debug easily.

Up to 36 points of captured input

The SoC in the MBs-PLC has a captured input function, which captures and stores the external pulse of an input shorter than the scanning time of the CPU. Compared to PLC’s in this class that either lack this capability or require highly sophisticated interrupt functions (which increase the CPU processing time), the MBs-PLC can handle this task easily as a general input, easily configured with high efficiency and no detriment the CPU scan time.

Single unit with 16 points of high-speed interrupt

The MBs-PLC provides 16 points of external interrupts. The interrupt is edge driven and the user can define which edge triggers the interrupt and can be positive, negative or both edges. The interrupts can perform high speed, emergency processing which can withstand the time jilter caused by the delay and deviation of the scan time and can be used for precision high speed positioning, machine home and high speed RPM measurement applications.